Project: Creation of an IoT-service of remote equipment monitoring and power consumption

Problem: the client’s company had no industrial network monitoring tools.

The only way to monitor the performance of the system was its internal inspection. When a non-standard operation occurred, the ability of quick response was limited.

There was no information about how many products each work shift makes. Thus, production forecast and delivery time guarantee were impossible (due to non-compliance with the deadlines, the company was forced to pay a penalty).

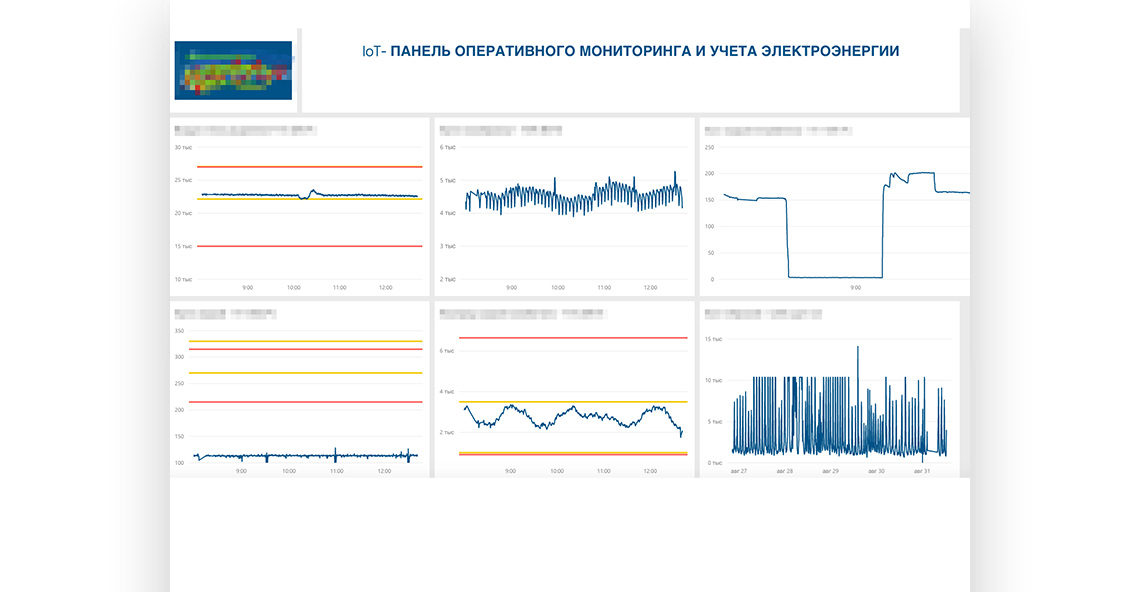

Solution: Maxilect was a subcontractor of this project. The hardware (iot-sensors that collect 40 parameters and transmit them using GSM modems) installation was made by our partner. We developed a business intelligence tool including performance monitoring and reporting systems built on the Power BI platform and Microsoft Azure as a data warehouse.

Information from iot-sensors is transmitted in JSON format to the servers located in Microsoft datacenters and processed by Azure and Power BI. An end-to-end chain of compatible reliability.

Outcome:

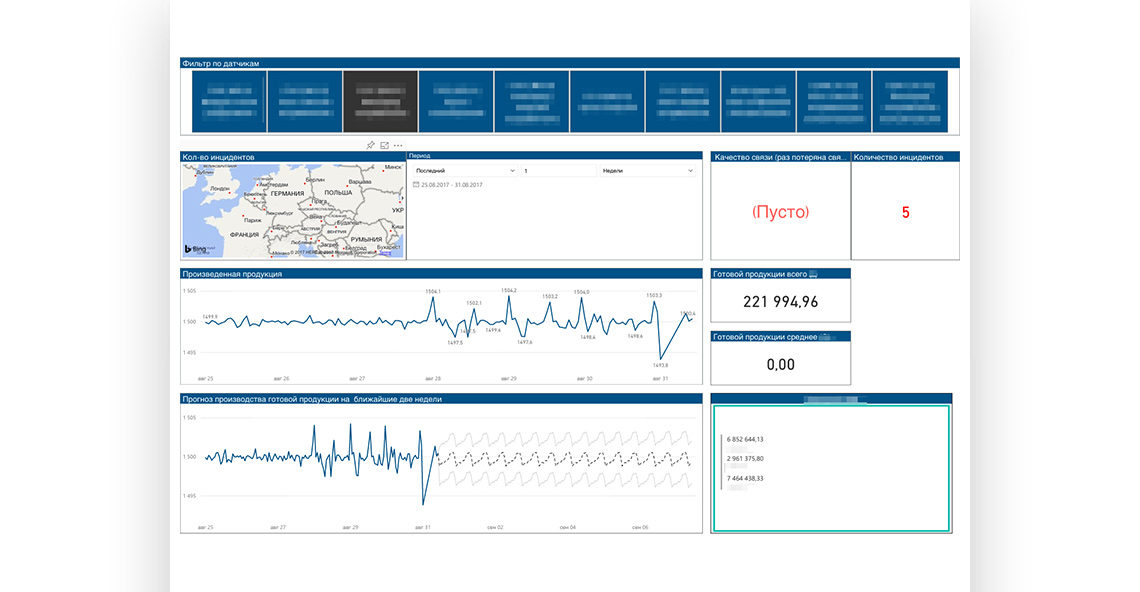

- real-time monitoring of iot-sensors and power consumption was achieved;

- The historical data is now collected at the Power BI platform for further performance forecasting and analysis;

- production volume is analyzing, so it allows us to build production forecasts on the upcoming weeks. With the long period historical data (for example, a year) it’s possible to build a more detailed forecast;

- real-time notification about station failures was created;

- our IoT-service is scalable horizontally – new iot-sensors can be added to the BI platform wich readings is counted in analytics (the only requirement is to evaluate the same parameters that are set up in the system);

- the staff was trained to work with the developed monitoring tools.

Technological stack: Power BI, Azure.